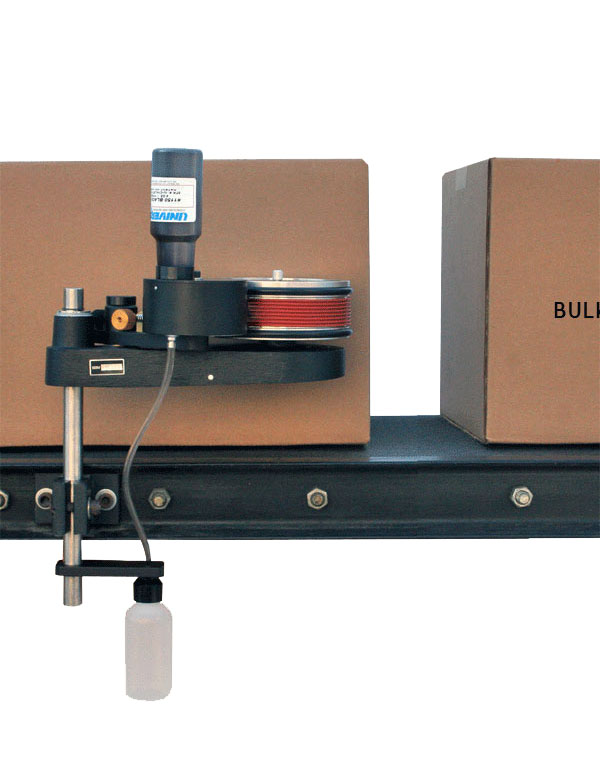

Universal Conveyor Line Printer

Model Shown: CLP-100

with optional Reservoir Roll Cover

Universal Conveyor Line Printers: The CLP Coders feature the largest print areas of any of our contact roll coders for printing on porous surfaces and are available in 4 different print widths, all featuring 18.0" Circumference Print Drums.

These machines are designed for extreme durability in high volume production printing applications. Optional Reservoir Roll Covers accept our patented 4 Oz. Disposable Ink Cartridges which feed ink to the Ink Rolls automatically during production.

Indexing models utilize dual compression springs, mounted over stainless steel guide shafts to provide the fastest and most durable print drum indexing system on the market today.

Non-Indexing Models have print drums which rotate freely on sealed ball bearings and print at random starting positions on cartons. These models are normally recommended for high speed conveyor lines where little or no space exists between cartons. In these applications, the print drum always remains in contact with a carton surface and the code information is printed at an interval equal to the print drum circumference (18.0"). Print repeat intervals can be reduced by installing multiple sets of dies on the print drum.

CLP-100NI 1-1/8" Non-Indexing Conveyor Line Printer - Print Area: 1-1/8" x 18.0"

CLP-200NI 2" Non-Indexing Conveyor Line Printer - Print Area: 2.0" x 18.0"

CLP-300NI 3" Non-Indexing Conveyor Line Printer - Print Area: 3.0" x 18.0"

CLP-400NI 4" Non-Indexing Conveyor Line Printer - Print Area: 4.0" x 18.0"

Indexing Models have print drums which return to the index position after printing each carton. This typically requires approximately 6" of space between cartons at 60 feet per minute conveyor speed and proportionally more space between cartons at higher speeds. The indexing feature enables the code to be applied to each carton at a registered position relative to the leading edge of the carton.

CLP-100 1-1/8" Indexing Conveyor Line Printer - Print Area: 1-1/8" x 18.0"

CLP-200 2" Indexing Conveyor Line Printer - Print Area: 2.0" x 18.0"

CLP-300 3" Indexing Conveyor Line Printer - Print Area: 3.0" x 18.0"

CLP-400 4"Indexing Conveyor Line Printer - Print Area: 4.0" x 18.0"